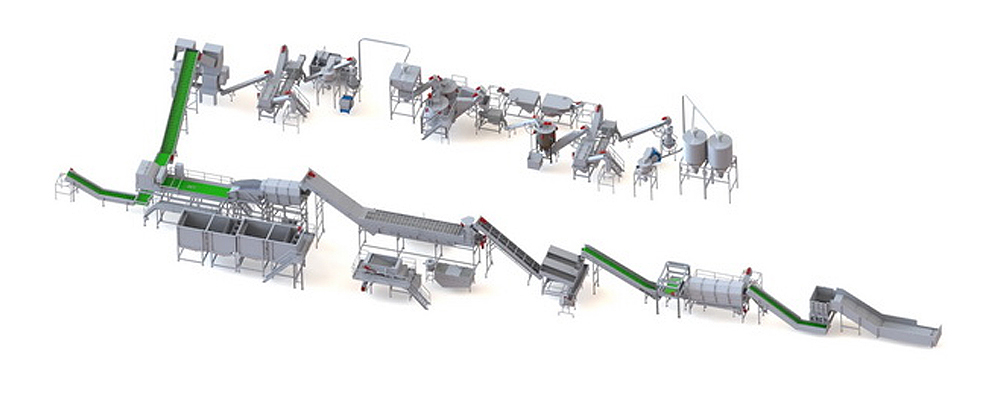

PET Bottle / Flakes Washing Line

PET Bottle / Flakes Washing Line is one of the main recycling series of KiTech machinery. This system applies to waste PET plastics recycling with different pollution levels. Which can remove ferrous and nonferrous metals, sand, oil, glue, rubber, wood, PE/ PP/ BOPP labels and many other different contaminants efficiently. It also provides a good solution for mixed color PET and materials containing PVC.The modular design makes it easy to have different combinations according to the requirements of the customers, such as bottle to fiber, bottle to flake, bottle to bottle washing system. KiTech provides 500-6000 kg/h economy and high-level automatical production lines with different configurations.

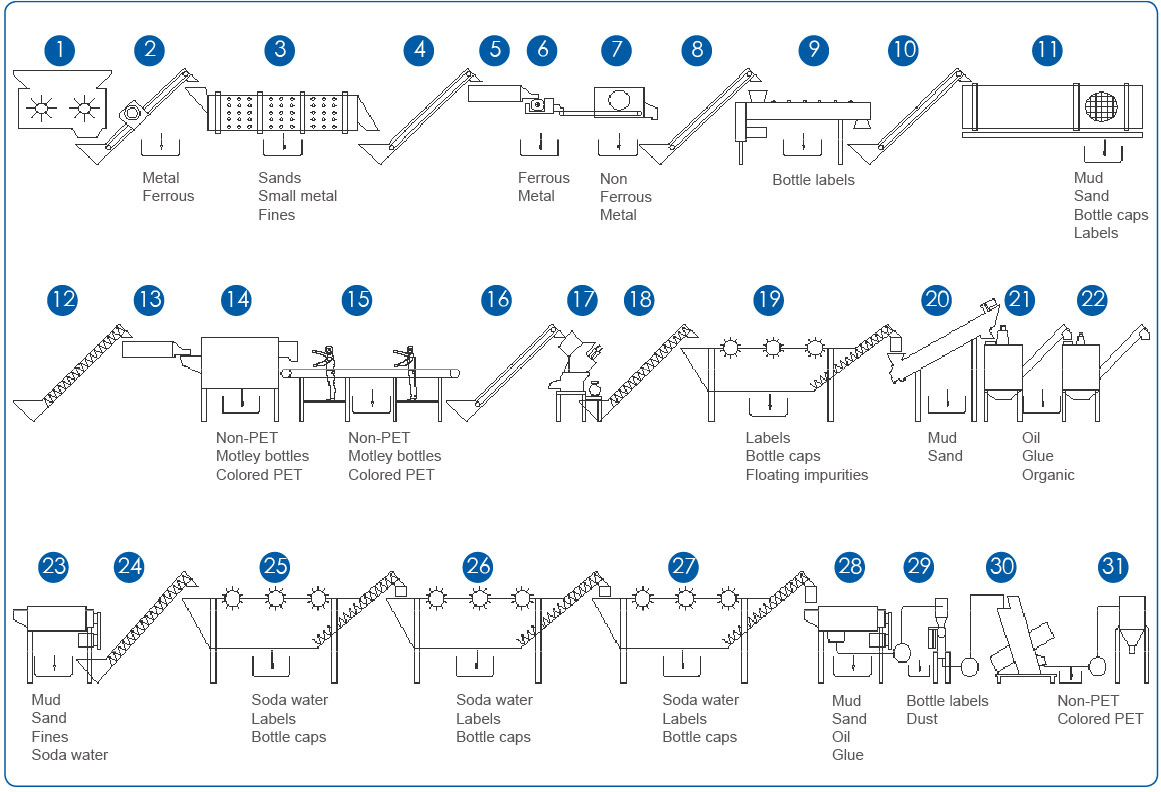

Metal sorting

Label remover

Pre-washer

Crusher

Hot washer

Friction washer

Floating washer

Centrifugal dryer

Zig-zag separator

Water treatment system

Color sorter

Material sorter

Ability

Thanks to innovative PET washing te chnology and high quality performance. KiTech intelligent recycling and washing system removes the most difficult contaminants from waste plastics, and provides high quality and purit washing results for customers

Stability

Kitech PET washing system is available for 24 hours working non-stop operation. Optimized design and top brand components to each module Which could minimize the downtime ratio and save the maintenance time. This ensures the maximum availability and highest productivity for user

Efficiency

Kitech PEt washing system is designed in all details for efficiency improving. The modular design could simplify the planning and accelerate the implementation. The system have very low consumption values for electricity, water and labor. The operating costs and maintenance costs are absolutely reduced Consistently the lowest investment costs and highest value creation

Modularity

Kitech PET washing system is a flexible modular system All elements required by any customer for different application could be combined freely. This design reduces planning, construction and assembly time effectively. And it's possible to adjust the system regard to te chnological modification and market changing. This makes the investment future-proofing

Control

Automatic modular control of KiTech PET washing system reduces the labor operation, makes the whole system easier and more reliable to control, the remotes monitoring and maintenance are available for different production lines. The intelligent control has display for operating data, it also collects the data of the consumption and the capacity from production line. Which ensures the connection between the enterprises and the Internet, will improve the efficiency of enterprise management

Service

KiTech PET washing system is a flexible and customer- oriented recycling solution. All the components of the /hole line is globally well-known brands, which ensures the reliable operation and serves your exact needs. Furthermore, Our engineers will partner with you for the whole project. Building design, overseas installation commissioning and training are available. Machine warranty with spares in stocking and in-time delivery Consistently quick and careful service in pre-sales and after-sales process

Electrical Parts

Technical Data

Sheet grade PET washing system

|

TYPE |

Capacity (kg/h) |

Energy consumption (kw/h) |

Steam consumption (kg/h) |

Chemical consumption (kg/h) |

Water consumption (ton/h) |

Installation power (kw) |

Space(m²) |

Man power (persons/shift) |

|

PET500 |

500 |

110 |

500 |

10 |

0.7 |

220 |

700 |

6 |

|

PET1000 |

1000 |

170 |

600 |

14 |

1.5 |

395 |

800 |

8 |

|

PET2000 |

2000 |

340 |

1000 |

18 |

3 |

430 |

1200 |

10 |

|

PET3000 |

3000 |

460 |

1200 |

28 |

4.5 |

590 |

1500 |

12 |

|

PET5000 |

5000 |

680 |

1500 |

50 |

8 |

850 |

2000 |

12 |

Fiber grade PET washing system

|

TYPE |

Capacity (kg/h) |

Energy consumption (kw/h) |

Steam consumption (kg/h) |

Chemical consumption (kg/h) |

Water consumption (ton/h) |

Installation power (kw) |

Space(m²) |

Man power (persons/shift) |

|

PET500 |

500 |

70 |

300 |

10 |

0.7 |

190 |

500 |

10 |

|

PET1000 |

1000 |

140 |

500 |

12 |

1.5 |

340 |

700 |

12 |

|

PET2000 |

2000 |

280 |

800 |

16 |

3 |

390 |

1000 |

16 |

|

PET3000 |

3000 |

350 |

1000 |

25 |

4.5 |

520 |

1200 |

18 |

|

PET5000 |

5000 |

590 |

1200 |

40 |

8 |

920 |

1500 |

25 |