AGX Heavy Duty Single Shaft Shredder

AGX/AGS/AGF/AGH

KEY FEATURES >

-Large diameter flat rotor

-Machined pocket knife holders

-Optional hard facing

-Concave ground square knives

-Robust ram construction

-Heavy duty guide bearings

-Universal couplings

-Low speed, high torque geared drive

-Powerful hydraulic swing type ram

-Reduced footprint (compared to horizontal pusher designs)

-Bolt in drive shafts

-Multiple rotor designs

-Two speed hydraulic system

-Oil cooling on ram and gearbox

-Ram comb plate -Amp meter control

OPTIONS >

-Hydraulic screen cradle

-Gearbox with shrink disc

-Rotor cooling -Pipe spacer

-Touch screen PLC

-Hopper mounted viewing mirror

-Increased motor drive

-Hydraulic drive

-Bespoke colour scheme

-Turbo hydraulics -Housing wear plates

GENERAL DESCRIPTION>

The AGX Heavy Duty Single Shaft Shredder has a 750mm diameter profiled rotor made of solid steel, operating at a speed of 52rpm. The concave ground, aggressive 4-way rotating knives are mounted in the grooves of the profiled rotor with special knife holders. This enables a reduction of the cutting gap between the counter knives and the rotor which guarantees a high flow rate, low power consumption and maximum output of shredded material. The hydraulically operated ram feeds the material automatically in the rotor's cutting chamber by load-related controls. The hydraulic system is equipped with high-pressure valves and volumetric flow controls which can be set according to the requirements of the input material.

Extremely robust pedestal bearing housings are mounted outside the machine and separate to the cutting chamber to prevent dust and dirt penetrating into the oversized bearings. This ensures a long service life andminimum service and maintenance. Power is transmitted from the motor by a drive belt via an oversized gearbox which is located on the shaft end on one end of the rotor.

A safety switch prevents machine startup when the front panel is open and the machine features emergencystop buttons on the machine body and control panel.

APPLICATIONS>

AGX Single Shaft Shredders have been designed with a wide range of applications and industries in mind such as: PLASTICS/WOOD/BIOMASS/PAPER/ALTERNATIVE FUELS(RDF/SRF)/DOMESTIC&DOMESTIC&COMMERCIAL WASTE

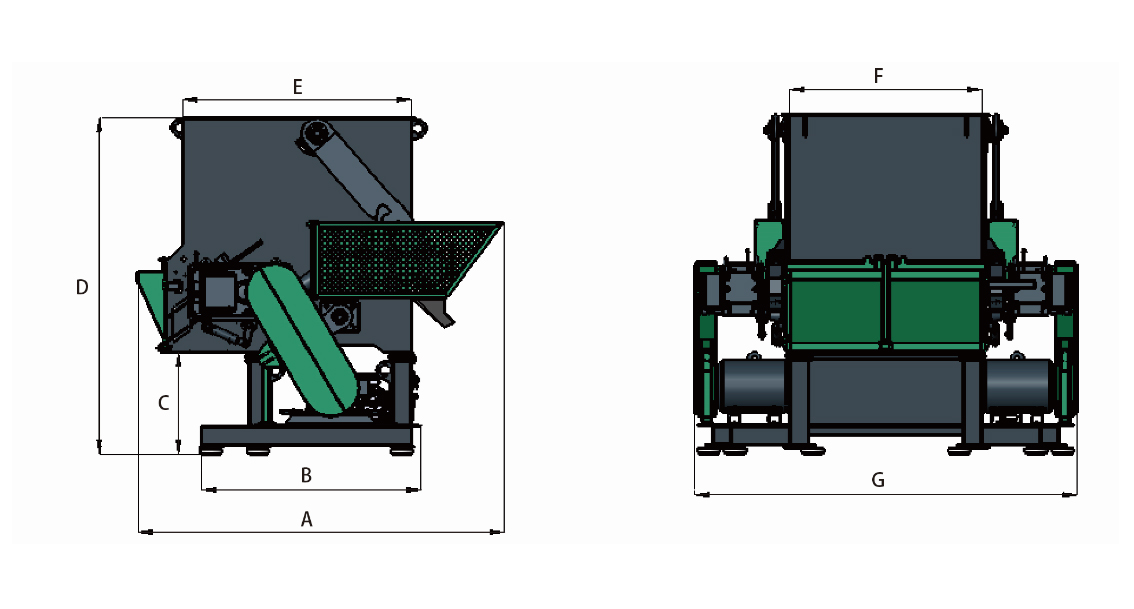

SPECIFICATION>

|

ITEM |

UNIT |

AGX1500 |

AGX2000 |

AGX3000 |

|

|

Cutting Chamber |

mm |

2540x1620 |

2540x2020 |

2540x2820 |

|

|

Rotor Diameter |

mm |

750 |

750 |

750 |

|

|

Rotor Speed |

rpm |

52 |

52 |

52 |

|

|

Main Motor Power |

kw |

2x75 |

2x90/2x110 |

2x132 |

|

|

Rotor Knives |

pcs |

76 |

96 |

136 |

|

|

Stator Knives |

row |

4 |

5 |

7 |

|

|

Hydraulic Ram Power |

kw |

11 |

11 |

11 |

|

|

Screen Size |

mm |

40-100 |

40-100 |

40-100 |

|

|

Effective Working Area |

mm |

1500x1490 |

1500x1900 |

1500x2700 |

|

|

Dimensions |

A |

mm |

3600 |

3600 |

3600 |

|

B |

mm |

2260 |

2260 |

2260 |

|

|

C |

mm |

870 |

870 |

870 |

|

|

D |

mm |

3350 |

3350 |

3350 |

|

|

E |

mm |

2540 |

2540 |

2540 |

|

|

F |

mm |

1620 |

2020 |

2820 |

|

|

G |

mm |

3500 |

4000 |

5000 |

|